-

Laboratory nano grinding machine

Product introduction

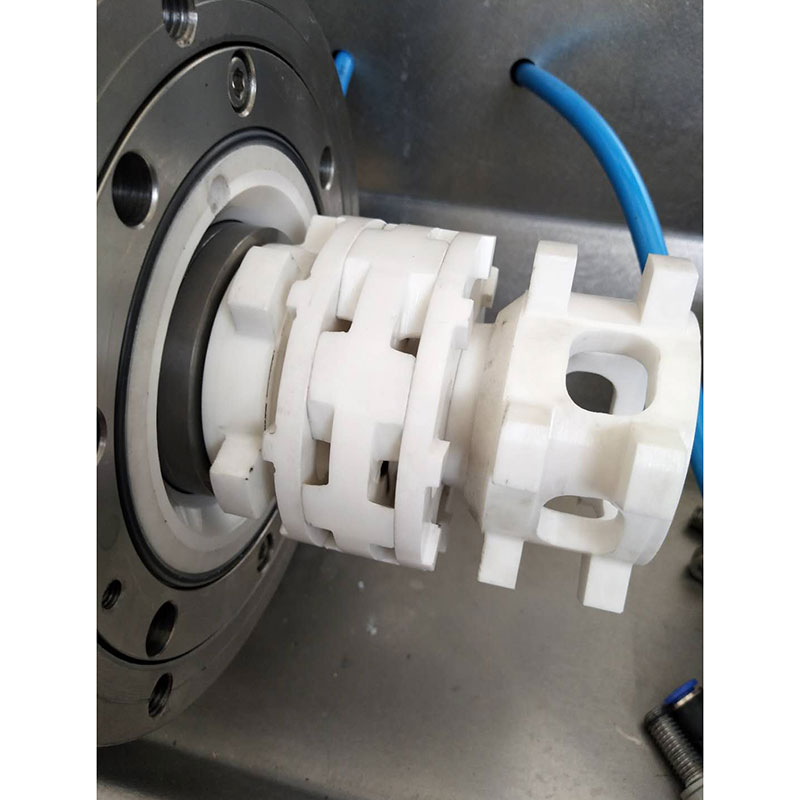

This product adopts advanced Japanese and American fluid grinding technology. The grinding rotor is made of high wear-resistant zirconia ceramic material, and the inner lining of grinding cylinder is made of silicon carbide ceramic material with good wear resistance and thermal conductivity, which has good wear resistance and long service life. The special rod pin structure of the rotor has high efficiency. All sealing parts need special PTFE, which is solvent resistant. This product is widely used in nano materials, ink, cosmetics, pesticides, medicine, ceramics and other high-end products.

Advantages: high configuration, stable performance, long life, no color change, no pollution, no maintenance, easy cleaning, simple operation, beautiful product!

Product characteristics

1. The equipment occupies a small area, the equipment is light and easy to move.

2. It can be used in a wide range of applications, and its efficiency is increased by 200% compared with the ordinary grinding machine.

3. It is suitable for fluid grinding below 10000 CPS.

4. The grinding fineness can reach below 100nm.

5. It is simple to use, easy to operate, with frequency conversion speed regulation function.

6. PLC touch screen operation is optional.

technical parameter

model(Mode & Spec.) electric machinery(Power for Press) KW Volume of grinding cylinder(Volume)L Processing batch(Yield)L Dimensions(Dimensions)mm Grinding medium(zirconia beads)mm LBD-0.2L 1.1 0.2 0.2-0.8 550*550*600 0.3-1.2 LBJ-0.6 4 0.6 0.3-10 600*340*650 0.1-1.2 LBJ-1 4/5.5 1 0.8-20 600*340*650 0.1-1.2 LBJ-2 5.5/7.5 2 2-50 800*700*900 0.1-1.2 LWJ-1 4 1 0.8-20 580*240*650 0.1-1.2